The 2-Minute Decision Matrix for Floor Supervisors

Make faster, better warehouse decisions with the 2-Minute Decision Matrix designed specifically for busy floor supervisors.

It's 2:37 PM on the warehouse floor. A critical conveyor belt suddenly stops. Production is backing up by the second. Three team members are looking to you for direction while your radio crackles with questions from other departments. You need to decide—now—whether to attempt a quick fix, call maintenance, or reroute product to another line.

Sound familiar? For floor supervisors and warehouse managers, this scenario isn't the exception—it's Tuesday afternoon. And Wednesday morning. And Friday before lunch.

The reality of operational leadership is that you'll make dozens of time-sensitive decisions every shift, often with incomplete information and multiple stakeholders waiting. Traditional decision-making approaches that work well in office settings or for strategic planning simply fall apart under the unique pressures of the production floor.

As I explored in Decision Making for New Warehouse Managers: Part 1, there's a critical distinction between consequential, irreversible decisions (Type 1) and everyday operational choices (Type 2). But even within Type 2 decisions, floor supervisors need a faster, more practical approach for the most time-sensitive situations.

Enter the 2-Minute Decision Matrix—a simple but powerful tool designed specifically for operational leaders who need to make sound decisions quickly in high-pressure environments.

Why Traditional Decision-Making Fails on the Floor

The production floor creates unique decision-making challenges that office-based managers rarely encounter:

Time compression: While office managers might have hours or days to consider options, floor supervisors often have seconds or minutes before indecision creates cascading problems.

Constant interruptions: The typical warehouse supervisor is interrupted every 3-5 minutes, making it nearly impossible to sustain the focused thought that traditional decision models require.

Information gaps: You're frequently working with partial information, as the full picture might be distributed across different team members or departments.

Physical constraints: Unlike office settings where you can quickly gather stakeholders in a room, production environments might have key people spread across a facility measured in acres rather than square feet.

Visibility impact: Decisions are highly visible, with team members watching how decisively and effectively you handle situations.

During my time managing a fulfillment center, I learned this lesson the hard way. Early in my career I remember spending twenty minutes analyzing staffing options during an unexpected volume surge, carefully weighing all possible scenarios—only to look up and realize that while I was deliberating, the problem had grown exponentially. The twenty minutes of careful thought actually created forty minutes of recovery work.

What I needed wasn't more analysis—it was a structured way to make good enough decisions quickly. That's precisely what the 2-Minute Decision Matrix provides.

The 2-Minute Decision Matrix Explained

The matrix is built on two simple dimensions that determine how you should approach any operational decision:

Impact Level: How significantly will this decision affect operations, safety, quality, or team dynamics?

Low impact: Affects a limited area or process with minimal consequences

High impact: Affects multiple areas, processes, or could have significant consequences

Reversibility: How easily can this decision be changed or undone if needed?

Easily reversible: Can be quickly changed with minimal disruption or cost

Difficult to reverse: Would be time-consuming, costly, or disruptive to change

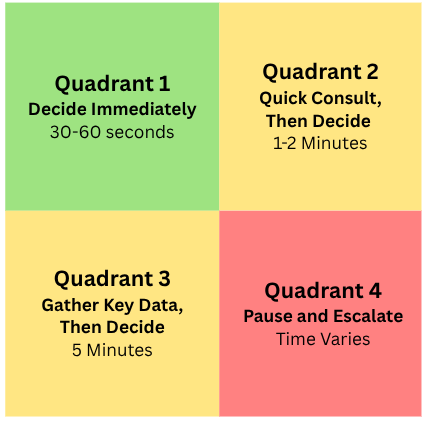

These two dimensions create a simple 2×2 matrix with four quadrants, each calling for a different decision approach:

Quadrant 1: Low Impact, Easily Reversible

Examples: Temporary staffing adjustments, minor workflow adaptations

Approach: Decide immediately based on available information and move on

Time investment: 30 seconds max

Quadrant 2: High Impact, Easily Reversible

Examples: Shifting to alternative workflow during equipment issues, implementing temporary process workarounds, reassigning significant resources

Approach: Quick consult then decide—get rapid input from 1-2 key people, then make the call

Time investment: 60-120 seconds

Quadrant 3: Low Impact, Difficult to Reverse

Examples: Changing how a specific product is handled, adjusting a documentation procedure, modifying a quality check process

Approach: Gather key data then decide—collect the critical information points, then make a decision

Time investment: 5 minutes

Quadrant 4: High Impact, Difficult to Reverse

Examples: Safety-related shutdowns, major production redirections, significant quality intervention

Approach: Pause and escalate—get appropriate authorization or expert input before proceeding

Time investment: Variable, but clearly recognize this requires a different process

This framework connects to the "Hat, Haircut, Tattoo" model discussed in Part 1 of this series. Quadrant 1 decisions are "Hat" decisions—easily changed if they don't work out. Quadrants 2 and 3 generally align with "Haircut" decisions—they matter more but will grow out eventually. Quadrant 4 decisions are potential "Tattoo" decisions—they'll have lasting effects and deserve appropriate consideration.

The power of this matrix is that it helps you quickly categorize decisions and apply the right level of deliberation without overthinking situations that don't warrant it.

Implementing the Matrix in Real-Time

Using the matrix effectively requires practicing a 30-second assessment when faced with a decision:

Quickly determine the impact level by asking: "If this goes wrong, what's the worst that could happen?" If the answer involves safety issues, significant quality problems, substantial lost production, or major team disruption, it's high impact. Otherwise, it's likely low impact.

Assess reversibility by asking: "How easily can we undo or adjust this decision?" If it would take minimal time and resources to change course, it's easily reversible. If changing would be difficult, disruptive, or expensive, it's difficult to reverse.

Locate your decision on the matrix and apply the corresponding approach.

For example, let's apply this to our opening scenario of the stopped conveyor belt:

Impact level: High (production is backing up and multiple areas are affected)

Reversibility: Easily reversible (any intervention can be quickly changed if ineffective)

Matrix position: Quadrant 2—Quick consult then decide

With this classification, you know to quickly consult with one or two key people (perhaps your most experienced team member or maintenance contact), then make a decision without further delay.

To maximize the effectiveness of the matrix, develop standard communication templates for each quadrant:

Quadrant 1: "This is a routine adjustment that we can easily change if needed. I'm implementing it now."

Quadrant 2: "This situation affects multiple areas but we can adjust our approach if needed. After a quick consultation with [person], we're going to [decision]."

Quadrant 3: "While this area is limited in scope, changing our approach later would be disruptive. Based on the key factors of [1-2 factors], we're going to [decision]."

Quadrant 4: "This situation has significant implications and would be difficult to reverse. I'm escalating this to [appropriate person/level] for a decision while we [interim action]."

These templates help you clearly communicate both your decision and your rationale, building trust in your decision-making process.

From Theory to Action

Ready to implement the 2-Minute Decision Matrix in your operational leadership? Start with these practical steps:

Print the pocket reference: Download and laminate the Decision Matrix template. Keep it with you during shifts until the framework becomes second nature.

Practice with past decisions: Review 5-10 recent operational decisions you've made. Plot them on the matrix and assess whether you applied an appropriate level of deliberation to each.

Conduct daily drills: For the next week, mentally classify at least three decisions each day using the matrix. Note which quadrant they fall into and whether your approach matched the recommended one.

Create team awareness: Brief your team on the basic matrix concept so they understand why some decisions are made immediately while others require more consultation or escalation.

Set decision time limits: Establish default timeframes for different types of operational decisions. For example: staffing adjustments (30 seconds), workflow modifications (60 seconds), quality interventions (5 minutes).

Track matrix effectiveness: Keep a simple log of decisions where using the matrix notably improved your response time or effectiveness. Use these examples to reinforce the habit.

Refine your quadrant borders: Based on your specific role and authority, personalize where the boundaries between "high" and "low" impact lie for your operation.

The 2-Minute Decision Matrix isn't about making hasty decisions—it's about applying the right amount of deliberation to each situation. As you practice this approach, you'll find yourself making better decisions faster, with less stress and more consistent results.

In our next installment, "Decision Making for New Warehouse Managers: Part 2 - High-Impact Decisions," we'll explore how to approach those Quadrant 4 decisions that deserve more substantial consideration. Until then, start implementing the matrix for your everyday operational decisions and watch how it transforms your effectiveness on the floor.

Remember to download the accompanying 2-Minute Decision Matrix template for a printable pocket reference you can use during your shifts.

Want to stop feeling overwhelmed by daily decisions? Join our community of operational leaders focused on practical skill development.